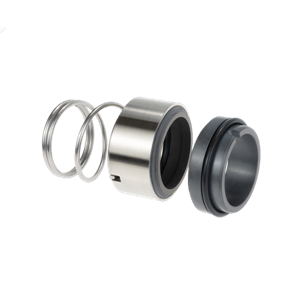

Conical spring,unbalanced,O-ring pusher construction

Conical spring,unbalanced,O-ring pusher construction  Torque transmission via conical spring, independent of direction of rotation.

Torque transmission via conical spring, independent of direction of rotation. Wide option in seal face material 。

Wide option in seal face material 。 Spring with deep coils to reduce the risk of clogging in solids content or viscous liquids.

Spring with deep coils to reduce the risk of clogging in solids content or viscous liquids. Paper and sugar industry,Food Processing,waste water technology

Paper and sugar industry,Food Processing,waste water technology Low solids content or viscous media

Low solids content or viscous media Sewage pumps, chemical pumps, screw pumps, process pumps

Sewage pumps, chemical pumps, screw pumps, process pumps Other Rotating Equipment.

Other Rotating Equipment.

Shaft diameter: d1=12...80mm

Pressure: p=0...1.0Mpa(145psi)

Temperature: t = -20 °C ...180 °C(-4°F to 356°F)

Sliding velocity: Vg≤15m/s(49.2ft/m)

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination materials

![]() Rotary Face

Rotary Face

Silicon carbide (RBSIC) O

Tungsten carbide W1

Cr-Ni-Mo Sreel (SUS316) G

Surface hardfacingtungsten carbide I

![]() Stationary Seat

Stationary Seat

Carbon graphite resin impregnated Ak

Silicon carbide (RBSIC) O

Tungsten carbide W1

![]() Auxiliary Seal

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR) P

Fluorocarbon-Rubber (Viton) V

Ethylene-Propylene-Diene (EPDM) E

![]() Spring

Spring

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G

Left rotation: L Right rotation: R

![]() Metal Parts

Metal Parts

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G

|

Standard Stationary Seat: T3G4 T3G4 equivalent to Burgmann G4 |

|

|

|

|

|

Alternatives Stationary Seat: T15G4 T8G13

T15G4 equivalent to Burgmann G4

|

|

|

|

|