Features

The seal components are available in a variety of materials to suit different applications.

Bi-directional

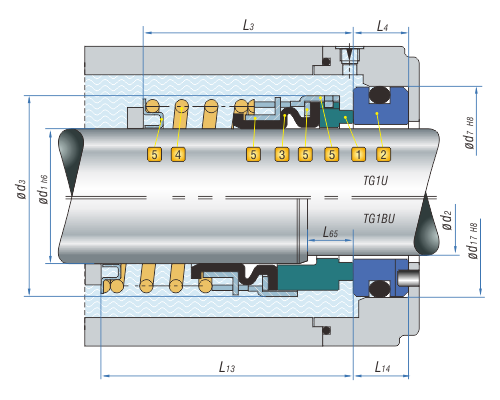

Available in multiple orientations: TG1BU (balanced version for higher pressure)

Compatible with multiple equipment OEM specifications

Simplified installation process enables quick replacements

Non-Pusher Design: The TG1 utilizes a non-pusher dynamic secondary seal, which accommodates axial movement without requiring sliding elastomeric elements. This reduces friction and prevents hang-up in the seal chamber.

Recommended Applications

Water and waste water technology

Process pumps

Industrial pumps

Petroleum chemical industry

General industrial rotating machinery

Other Rotating Equipment

Operating range

Shaft diameter: d1=0.625'' ...3.000''

Pressure: p=0...6.3Mpa(914psi)

Temperature: t = -20 °C ...205 °C(-4°F to 401°F)

Sliding velocity: Vg≤13m/s(42.6ft/m)

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination materials

Product Structure

Combination Materials

1. Rotary Face

Carbon graphite resin impregnated Ak

Silicon carbide (RBSIC) O

Hot-Pressing Carbon Ac

Tungsten carbide W1

2. Stationary Seat

Aluminium oxide(Ceramic) B

Silicon carbide (RBSIC) O

Tungsten carbide W1

3. Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR) P

Fluorocarbon-Rubber (FKM) V

Ethylene-Propylene-Diene (EPDM) E

4. Spring

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G

5. Metal Parts

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G