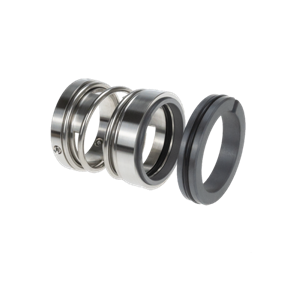

Wave spring、balanced、O-ring pusher construction.

Wave spring、balanced、O-ring pusher construction. Transmission by Pin and groove,independent of direction of rotation .

Transmission by Pin and groove,independent of direction of rotation . Spring-protection design.

Spring-protection design. Low risk of clogging in solids content or viscous liquids

Low risk of clogging in solids content or viscous liquids Paper and sugar industry, sewage treatment industry

Paper and sugar industry, sewage treatment industry solids content or viscous media

solids content or viscous media Sludge pumps, multistage pumps

Sludge pumps, multistage pumps Other Rotating Equipment.

Other Rotating Equipment.

Shaft diameter: d1=16...100mm

Pressure: p=0...1.6Mpa(232psi)

Temperature: t = -20 °C ...200 °C(-4°F to 392°F)

Sliding velocity: Vg≤20m/s(65.6ft/m)

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination materials

![]() Rotary Face

Rotary Face

Silicon carbide (RBSIC) O

Carbon graphite resin impregnated Ak

Antimony Impregnated Carbon Ad

![]() Stationary Seat

Stationary Seat

Silicon carbide (RBSIC) O

Tungsten carbide W1

![]() Auxiliary Seal

Auxiliary Seal

Fluorocarbon-Rubber (Viton) V

Ethylene-Propylene-Diene (EPDM) E

![]() Spring

Spring

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G

![]() Metal Parts

Metal Parts

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G

|

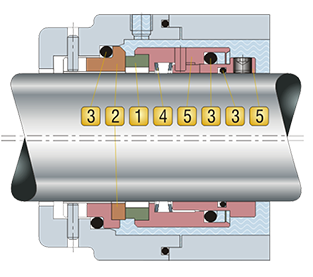

Standard Stationary Seat: T7G16 T7G16 equivalent to Burgmann G16 |

|

|

|

|

|

Alternatives Stationary Seat:T5G46 T5G46 equivalent to Burgmann G46

|

|

|

|

|